RPET stands for Recycled Polyethylene Terephthalate. It is a type of fabric that is made from recycled plastic bottles, specifically those made of polyethylene terephthalate (PET). RPET recycled fabric is produced through a process that involves collecting discarded plastic bottles, cleaning them, and transforming them into polyester fibers.

Here's a simplified overview of the production process:

Collection: Plastic bottles made of PET are collected from recycling centers or waste management facilities.

Sorting and Cleaning: The collected bottles are sorted based on their color and cleaned to remove any impurities or contaminants.

Shredding and Pelletizing: The cleaned bottles are shredded into small pieces and then further processed into small pellets or flakes.

Melting and Extrusion: The pellets are melted down and extruded into fine filaments.

Spinning: The filaments are spun into yarns, which can then be woven or knitted into fabrics.

Dyeing and Finishing: The RPET fabric can be dyed using eco-friendly dyes, and additional finishing processes can be applied to enhance its properties, such as softness or water resistance.

RPET recycled fabric is considered a more sustainable alternative to traditional polyester fabric because it reduces the dependence on virgin resources, conserves energy, and helps divert plastic waste from landfills and oceans. It can be used in various applications, including clothing, bags, upholstery, and other textile products.

RPET (Recycled Polyethylene Terephthalate) is a type of recycled fabric made from PET plastic bottles that have been collected, sorted, cleaned, and processed into polyester fiber. Here are some of the advantages and characteristics of RPET recycled fabric:

Environmentally Friendly: RPET recycled fabric is a sustainable alternative to traditional polyester fabrics, as it reduces waste and conserves resources by reusing discarded plastic bottles.

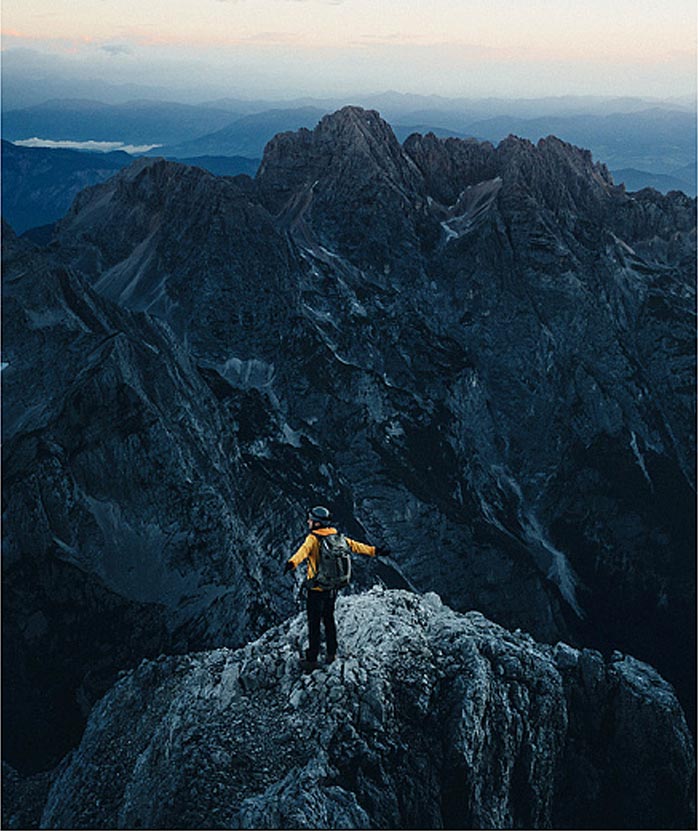

Durability: RPET recycled fabric is durable and long-lasting, making it suitable for use in a range of products, including clothing, bags, and outdoor gear.

Moisture-wicking: RPET recycled fabric has moisture-wicking properties, which make it ideal for use in sports and activewear. It can help to keep the wearer cool and dry by wicking away sweat and moisture from the skin.

Softness: RPET recycled fabric is soft and comfortable to wear, and it can be treated to have a range of textures and finishes.

Customizable: RPET recycled fabric can be customized to meet specific design and performance requirements. It can be dyed, printed, and finished to achieve a range of colors, patterns, and effects.

Cost-effective: RPET recycled fabric can be produced at a lower cost than traditional polyester fabrics, as it does not require the extraction of new raw materials.

RPET recycled fabric offers many advantages, including sustainability, durability, moisture-wicking properties, softness, customizability, and cost-effectiveness. As a result, it is becoming an increasingly popular choice in the fashion and outdoor industries.

EN

EN  English

English 简体中文

简体中文